From CBS to Corona: How Fender Rebuilt Its Reputation

The story of how Fender clawed its way back from corporate chaos to global respect

If you’re old enough to have played a few CBS-era Fenders, you’ll know the reputation they carry.

By the mid-1970s, Fender had gone from Leo’s precision-built Californian masterpiece to a sprawling corporate machine under CBS. Production volume was up — but quality wasn’t. The guitars often felt heavy, inconsistent, and soulless. By the early ’80s, even loyal players were defecting to boutique builders or Japanese copies. Fender’s name, once sacred, had become a warning label.

And yet, just twenty years later, Fender was not only back — it was thriving.

Today, the brand’s reputation for craftsmanship and heritage is stronger than ever. The turnaround between 1981 and 1987 is one of the most dramatic recoveries in guitar and business history.

Let’s trace exactly how Fender did it.

1965–1981: The CBS Decline

In 1965, Leo Fender sold his company to CBS for roughly $13 million. CBS scaled up production fast, building larger facilities and eventually introducing cost-saving design tweaks — three-bolt necks, bullet truss rods, thicker polyester finishes.

On paper, efficiency improved. In the hands of musicians, the magic disappeared.

By the late ’70s, quality control was a running industry joke. Even Fender’s U.S. dealers complained of guitars that needed neck resets straight out of the case. Vintage pre-CBS Fenders started fetching a premium simply because they were better than new ones, and for the first time, new didn’t mean better.

1981–1984: The Dan Smith Rescue Plan

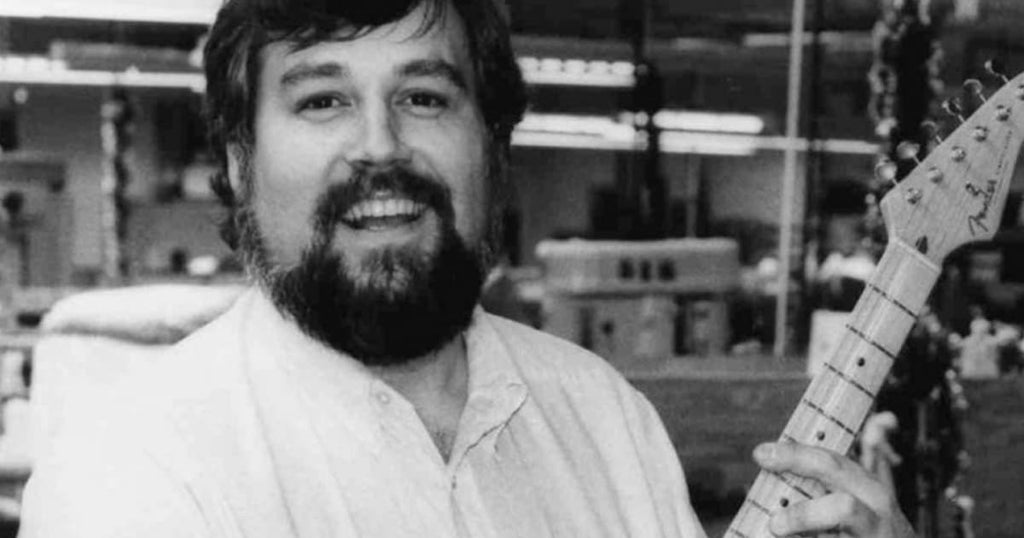

In 1981, CBS realised the brand was in free fall. They brought in Bill Schultz (formerly Yamaha USA) and hired Dan Smith, a player and marketing man who actually understood guitars.

Dan Smith

Joined Fender in 1981 from Yamaha.

Tasked with rationalising production and restoring credibility.

Oversaw the ’82 Vintage Reissue Series and American Standard development.

Smith and Schultz did something radical: they slowed production and focused on fixing quality.

By 1982, the “Smith Strat” appeared — a tidier, better-built instrument signalling the end of the bloated CBS mindset. While the Smith Strats reverted back to the original design in many ways (four bolt neck, small headstock, body end truss rod, deep contours) they failed to reproduce one thing accurately.... The Headstock!

That same year, Fender quietly introduced its first true Vintage Reissues: the 1957 and 1962 Stratocasters. Using original instruments as reference, these models marked the first serious attempt to reconnect with Fender’s golden age & they were truly excellent guitars. The early examples (circa 1982-84) remain sought after and rare.

Meanwhile, CBS struck a deal with FujiGen in Japan to produce the JV (Japanese Vintage) and Squier JV lines. These guitars were so good that, ironically, they helped save Fender’s reputation overseas while the American operation was still in disarray.

1985: The Buyout — CBS Walks Away

By the mid-1980s, CBS had had enough. Guitar sales were shrinking, competition was fierce, and Fender’s Fullerton plant was inefficient. In March 1985, a group led by Bill Schultz and John McLaren negotiated a management buyout, forming Fender Musical Instruments Corporation (FMIC)

Bill Schultz

Led the 1985 management buyout from CBS.

Became CEO of FMIC and served until 2005.

Often credited as the man who “saved Fender.”

Crucially, CBS did not sell the Fullerton factory.

FMIC bought the name, designs, and inventory — but no manufacturing facility. For a brief period, there was no Fender guitar factory in America. Production continued in Japan while Schultz scrambled to rebuild a U.S. operation from scratch.

This clean break turned out to be Fender’s salvation. With no legacy plant or CBS bureaucracy, Schultz had the freedom to start fresh.

1986–1987: The Rebirth at Corona

By 1986, Schultz had secured a new facility in Corona, California. It wasn’t fancy — just a few thousand square feet and a handful of employees — but it marked the rebirth of Fender USA.

That same year, Fender began work on a new flagship model: the American Standard Stratocaster, launched in 1987. Designed by George Blanda and Dan Smith, it combined modern playability (two-point tremolo, flatter radius, improved neck pocket) with the feel of a classic Strat. It became the backbone of Fender’s reputation for decades.

And as if that wasn’t enough, 1987 also saw the creation of the Fender Custom Shop — spearheaded by John Page and Michael Stevens. This was Fender’s statement of intent: we’re back, and we can build as well as we ever did.

John Page & Michael Stevens

Founded the Fender Custom Shop in 1987.

Combined bespoke craftsmanship with artist collaboration.

Re-established Fender as a builder of world-class instruments.

Within its first few years, the Custom Shop built guitars for Clapton, Beck, and Gilmour — and just like that, Fender’s prestige was reborn.

1990s: Expansion and Consistency

Through the 1990s, Fender grew into a global powerhouse again.

-

Ensenada, Mexico, opened in 1987 to handle mid-tier models, then rebuilt after a 1994 fire into a modern production hub.

-

The U.S. Corona plant scaled up for the American Standard and Custom Shop lines.

-

Artist signatures (Clapton, Malmsteen, SRV) reinforced Fender’s cultural presence.

The formula was simple: modern reliability, classic tone, and a halo of Custom Shop excellence at the top.

By the end of the decade, Fender had gone from near-bankruptcy to industry benchmark.

2000s Onward: Investment and Perfectionism

In 2001, private equity group Weston Presidio took a controlling stake, giving Fender the capital to modernise both Corona and Ensenada.

This funding wave directly underpinned the mid-2000s Custom Shop leap in quality that I explored in last week’s article.

By the time Fender filed its IPO papers in 2012, the S-1 document showed a company reinvesting heavily in U.S. manufacturing and high-end R&D. The market didn’t cooperate, and the IPO was pulled, but the data told the story: Fender had become a disciplined, profitable, quality-driven manufacturer again.

In 2020, ownership passed to Servco Pacific, a long-term Fender partner since the 1980s — ensuring continuity and stability for the next era.

Why Fender’s Rebuild Worked

-

Leadership with vision. Schultz and Smith were guitar people first, executives second. They made the hard calls.

-

Clean slate manufacturing. Starting from zero at Corona allowed Fender to rebuild quality without CBS baggage.

-

Smart use of Japan. JV and Squier models kept the brand alive globally while the U.S. rebooted.

-

Modern meets vintage. The American Standard balanced innovation with tradition — the perfect antidote to CBS’s excesses.

-

Prestige through craftsmanship. The Custom Shop redefined “Made in USA” as a badge of excellence.

From Darkness to Daylight

By any measure, the Fender of 1981 and the Fender of 1987 were two entirely different companies.

The first was a corporate husk producing guitars by committee.

The second was a reborn craftsman’s brand that would go on to define modern electric guitar culture for the next 40 years.

That’s the real story of Fender’s reputation: it wasn’t luck, and it wasn’t marketing.

It was a complete cultural rebuild — led by players, executed by craftsmen, and grounded in respect for what made those early instruments great in the first place.

Written by Julian Deverell – Coffee House Guitars

For collectors, players, and those who believe great guitars come from great people.